If you want to custom-order t-shirts for your bridal party or a family event, you will need to decide what type of printing to use. Every printing technique has its own style and level of complexity. With so many different types of printing on t-shirts available, how do you know which one to choose?

The most popular types of printing on t-shirts include direct to garment, sublimation, and screen printing. Techniques such as vinyl cutouts, heat transfers, and stenciling work well for small-scale printing jobs. Other options include indirect screen printing, discharge printing, and airbrushing.

In this article, you will find out how the ten most popular types of t-shirt printing work. You will learn which t-shirt printing methods last the longest and cost the least. Finally, you will find tips for how to print your own t-shirt at home!

Quick Navigation

- What Are the Types of Printing on T-Shirts?

- Different Types of T-Shirt Printing Methods: Comparison

- Best T-Shirt Printing Method

- Best Way to Print Cotton T-Shirts at Home

- Which Type of Printing is Best for Polyester T-Shirts?

- What is the Most Durable Kind of T-Shirt Printing?

- How to Print on T-Shirts at Home

- Conclusion

What Are the Types of Printing on T-Shirts?

You can print on t-shirts using different techniques such as applying ink directly onto the fabric, applying ink to a paper or transfer that then attaches to fabric, or even cutting out vinyl to attach to the fabric of the shirt.

Every method requires some specialized equipment and supplies. Some need expensive commercial technology, while others can work with basic craft supplies. This means that some types of printing may require pretty high start-up costs.

Another thing to keep in mind is that some methods work better on specific fabric types, like polyester vs cotton.

Finally, certain methods of printing work well for just one or two shirts, while others require so much setup work that you will see a much better return on your investment if you can handle large batches of shirts at one time.

Check out this overview of how all the major types of t-shirt printing work!

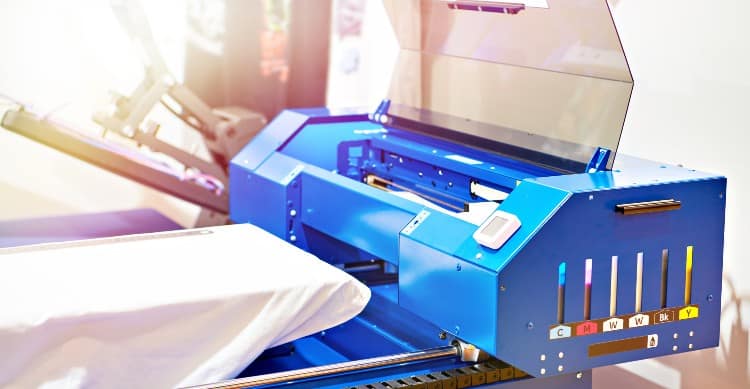

1. DTG

DTG stands for direct to garment printing. You may also occasionally see this method called DTF, or direct to fabric printing. The process does exactly what it sounds like–a special printer applies a thin ink right onto the fabric of the t-shirt!

This means that you can easily create any design that you could print onto paper. You can use many colors, create complex graphics, or even use photos. The ink soaks into the fabric of the shirt somewhat, meaning that the design feels soft to the touch instead of forming a stiff layer on top of the fabric. Another advantage of this method is that you can quickly run off one design after another without any complex setup.

So, what are the disadvantages of the DTG method? Well, buying a good DTG printer will set you back by anywhere from $10,000 to $500,000. So if you plan to launch a t-shirt business, this start-up cost is probably worth it, but obviously, this is not the best choice for a home artist!

While you can pretty easily set up and operate a DTG printer once you master the basics of the technology, you will need some understanding of graphic design to set up the designs on a computer first.

Finally, though DTG designs look very cool, they do not hold up long-term and some other kinds of designs.

2. Indirect Screen Printing/Plastisol

Plastisol or indirect screen printing has a growing popularity among t-shirt designers these days. This method combines some of the basics of screen printing and uses the kind of plastisol inks used in screen printing. The key difference is that the artist applies the ink onto a plastisol transfer sheet instead of directly onto the fabric.

The transfer sheet then gets heat pressed onto the t-shirt, creating a durable, raised design on the fabric’s surface.

To cut costs, some designers make a digital design and send it out to a third party who can easily mass-produce the design on plastisol sheets. The artist then uses heat to apply the plastisol sheet to a shirt.

Pros of this method include high quality, durable designs. Plus, you will have much less mess and set-up time than you would for regular screen printing. If you outsource the plastisol transfer sheet printing, you really only need to do the digital graphic design and then have a heat press on hand to finish the shirt!

The cons of this method include the fact that applying plastisol transfers can get tricky. When done incorrectly, the designs will crack and peel away later on. Also, this method works great for small orders but not as well for bulk orders.

3. Vinyl

Using heat transfer vinyl is one of the most popular shirt decoration methods for professionals and home artists. HTV vinyl is a special type of vinyl that has one decorative side and one side coated in a heat-activated adhesive. You can cut out lettering, logos, or even complex images from the vinyl, and then use heat to seal the cut out onto the fabric.

While not technically a “printing” method, many artists use vinyl basically in place of ink to create raised, durable designs on t-shirts. Large-scale professional operations will probably use enormous commercial cutting machines to create vinyl designs. However, at-home artists also love this method because you can also make your vinyl cut-outs using a simple electronic cutting machine like a Cricut.

You will find many variations on the basic plasticky vinyl you can use as well, including glitter vinyl, flocked or velvety vinyl, and metallic vinyl.

Using Heat Transfer Vinyl gives you a lot of flexibility for small=scale orders or even just for at-home use. If you want to make t-shirts for your child’s basketball team, you can get up and running with nothing but a cutting machine and an iron! If you want to start a small business, you can use little more than a Cricut and a heat press to get off the ground, too.

Besides the low start-up cost, making an HTV design generally does not take much time or work compared to many other methods. Plus, HTV designs have better durability than almost any printed design.

The downside to using HTV is that it does not work well for mass orders because you have to cut out the HTV repeatedly for each shirt. You also can’t use HTV on a heat-sensitive fabric because you need to use a heat press to activate the adhesive on the vinyl.

4. Heat Press Printing

Heat press printing is a good option for a beginner or at-home artist, though it typically does not offer the high quality of some other methods. That said, some professionals or small business owners do successfully offer heat press printed shirts for sale.

Heat press printing uses an inkjet or laser printer to print a design off of a computer. You must print onto a special kind of paper called iron-on transfer. You then use an iron or a heat press to glue the design onto your shirt!

This method works great for at-home designers because of the easy setup and low start-up cost. It allows you to create complex designs or photos just as easily as you would on paper. You have to master graphic design software if you want to create original artwork, but you can also just use images you find online or photos you snapped on your cell phone!

On the other hand, heat press printing may not hold up quite as well as screen printing or HTV designs. It also does not usually work on dark-colored shirts because the designs will not show up well without a light background. Finally, this method does require high heat, so you can’t use it on heat-sensitive fabric.

5. Sublimation

Sublimation printing is the best professional way to print on polyester material. However, it does not work on other kinds of fabric with all-natural fibers, like cotton. This cool but very costly method uses heat to turn dye into a gas that bonds with the fabric.

Sublimation printing creates soft, permanent designs on synthetic materials like polyester. Because of the unique way the dye sticks to the fabric, it leaves the cloth feeling breathable instead of creating a thick coating on the material. This also means that sublimation designs won’t crack or peel.

The disadvantage of this technique is its cost. You need a lot of commercial equipment for this process, making it more cost-effective for a large business than for home use or a small business. Also, you cannot use the sublimation method on cotton t-shirts.

6. Heat Transfer Printing/Inkjet

Heat transfer printing can work in several different ways. You can use it in the same way as the heat press method described earlier. You can also print your design onto vinyl and then use a heat press to seal the vinyl onto the shirt.

Either way, using an inkjet printer to put a design on some type of transfer makes for a pretty easy process. You do not need an expensive printer or lots of special supplies. However, it does take a considerable amount of time to set up each transfer and then heat press it to the shirt.

One of the pros of heat transfer printing with an inkjet printer is that you can easily try this at home. You will get decent quality in your design and can use a complex image such as a photo if you want.

That said, this method does take more time than lots of other processes. It is not usually the method chosen by professionals for that reason. It also creates a stiff layer on top of the fabric that may not feel comfortable, and designs will only show up on white or light-colored shirts.

7. Screen Printing

Screen printing is one of the highest-quality types of t-shirt printing out there, and it also gives a lot of room for creativity and artistry. It is also one of the oldest printing methods in the world!

To screen print, you create a negative of the design you want on a screen. You then roll a special ink called plastisol ink over the screen and press the screen onto the t-shirt. This forces the ink through the negative-space stencil on the design and creates an image on the shirt!

You can make quite complex screen prints using special chemicals to create photo-realistic stencils on screens. Or you can screen print in a very basic format by using a Cricut to make a stencil for the screen.

Screen printing has a lot of advantages that make it a popular choice for high-quality professional t-shirt designers, as well as for home artists. First, it creates vibrant, very durable designs. These do have a raised and slightly stiff feel on top of the fabric, but the ink soaks into the material, which makes it more durable even than an HTV design.

Second, screen printing offers a cost-effective way to make bulk orders of the same shirt because you can reuse the ink screen you laboriously set up for the first shirt.

Finally, you can screen print on pretty much any fabric, from silk to cotton to polyester.

Of course, you may also encounter some potential downsides to this popular method. You need space to work and pretty large equipment like the screens and the press to align the screen with the shirt. If you want to make complex designs, you also need special chemicals to work with. Finally, screen print designs usually work best when they involve one to three colors because you have to layer on each color one screen at a time.

8. Airbrushing

Airbrushing is not the best t-shirt design choice for a big commercial operation, but it remains extremely popular among artists and small-scale business owners. This method of t-shirt design allows for incredibly complex and artistic designs. You can also use this method as a unique substitute for screen printing by airbrushing over stencils, one color layer at a time.

The advantages of this method include its versatility. If you have ever seen an airbrush artist work on painting a caricature in a public park, or perhaps a chef use a food-safe airbrush to decorate a cake, you know how elaborately they can paint with this tool!

Another cool thing about airbrushing is that it does not cost much to get started, and you can also mix and use several different kinds of paints or dyes.

The downside to airbrushing is, first and foremost, the time involved. While this method allows for many artistic expression, it can take hours to make one shirt. It may also prove challenging to replicate shirts exactly if you want more than one of the same design.

9. Discharge Printing

Discharge printing does not get used a lot, but it creates a unique t-shirt. This process works by removing color instead of applying color! The printer uses a stencil to protect the design portion of the shirt and then bleaches away the rest of the dye, leaving only the design left in color.

You may enjoy trying this technique at home with a group of friends to create stylish vintage-looking tees. The big advantage of this technique is its one-of-a-kind appearance.

But while this process does create unique, vintage-style tees, it is time-consuming and costly, making it unpopular with professionals.

10. Stenciling

Stenciling is the most basic method you can use on t-shirts at home. You can cut out a stencil by hand or use a more advanced tool like a Cricut to electronically cut out digital designs. You then apply dye over the stencil, creating a logo or design on the shirt!

Professionals often used more advanced forms of stenciling in methods such as screen printing. However, you can replicate this at home with really simple tools if you just want to make a few fun shirts for your family!

The pros of stenciling are that you can make it as complex or simple as you want. Also, you do not need fancy technology or expensive equipment. You don’t even have to use a heat press, though you usually get more permanent results if you heat set a fabric design in some way.

The cons are that this simple method works better for personal use and will not give you the professional design you need if you want to sell shirts.

Different Types of T-Shirt Printing Methods: Comparison

If you feel a bit overwhelmed by all those pros and cons, take a look at this at-a-glance comparison of the most popular t-shirt printing methods.

| Quality | Design Options | Durability | Cost | Complexity | Time | Number of Prints | |

|---|---|---|---|---|---|---|---|

| DTG | High | High | Medium | High | low | Low | High |

| Indirect Screen Printing/Plastisol | High | Medium | Medium | Medium | High | Varies | Varies |

| Vinyl | High | Low | High | Low | Low | Varies | Low |

| Heat Press Printing | Medium | High | Medium | Low | Low | Low | Medium |

| Sublimation | High | High | High | High | High | Medium | Varies |

| Heat Transfer Printing/Inkjet | Medium | High | Medium | Low | Low | Low | Medium |

| Screen Printing | High | Medium | High | High | High | High | High |

| Airbrushing | High | Very High | Low | Low | High | Very High | Very Low |

| Discharge Printing | High | Medium | High | High | Medium | High | Low |

| Stenciling | Low | Low | Low | Low | Low | Varies | Low |

Best T-Shirt Printing Method

The best t-shirt printing method for you depends on your particular needs, such as how many shirts you want, whether you plan to work with polyester or cotton, and how durable you want your design to remain long term.

Check out these “best of” categories to find out which printing method will give you the best design options, the highest quality, the greatest durability, and so on!

Design Options

Several printing methods allow you to create highly complex designs, including DTG, sublimation, and heat press printing.

That is not to say that you can’t create more elaborate or complex designs with other methods, of course! But a process such as screen printing requires a lot of fancy equipment to replicate a photo, while the DTG process prints it directly onto the fabric.

Any printing process that works one color layer at a time, like HTV or screen printing, is often limited to one, two, or three-color designs.

Quality

Generally speaking, you will get the best quality designs on polyester shirts using a sublimation method, while screen printing offers the best quality designs for cotton. For a retro look, the best quality designs usually come from the HTV method or using a discharge printing method.

That said, design quality depends on a huge number of factors like the skill of the artist, and even on the quality of the fabric in the shirt! Under the right circumstances, you could create a high-quality t-shirt design using any of the methods explained in this article.

Cost

Overall, the DIY t-shirt printing methods like stenciling usually cost the least, while commercial-grade production methods like discharge printing or DTG cost the most.

You have to consider both start-up cost and cost per shirt as you select a method, though. Many of the methods described in this article do need expensive equipment. But once you have that equipment, you can create each shirt for a very low cost!

Time

T-shirt printing methods like DTG or the heat transfer method that use a printer to print a design out usually take the least amount of time. Screen printing and processes that layer colors one by one often take the most time.

On the other hand, you also have to consider whether or not a method can create more than one shirt. Screen printing takes forever to set up, but you can quickly roll out duplicates of the same design once you finish getting everything ready!

Durability

Several printing methods offer very durable designs, including sublimation and screen printing. Many designers especially like screen and sublimation printing because of the way the dye actually soaks into or bonds with the fabric during these processes.

A design that rests on the surface of the fabric usually will not last quite as long, as you face the danger of the raised design cracking or peeling away eventually. That said, well-made HTV designs should last for many years, so they have pretty excellent durability, too!

Complexity

Sublimation, screen printing, and airbrushing require a pretty high level of skill to complete the complex processes. That said, you can use a simpler version of screen printing and airbrushing at home, too. Likewise, processes like DTG can be operated quite simply, but require a lot of complex technology.

You really find varying levels of complexity in every different technique, depending on whether or not you plan to work on a commercial scale.

Type of Fabric

Certain printing methods only work on some fabric types, such as sublimation printing that only works on polyester. Also, any printing process that requires high heat, such as heat press or transfer printing, will only work on sturdy fabrics that can resist high temperatures, such as cotton.

Finally, some methods can work on almost any kind of fabric. These include screen printing and stenciling.

Supplies

Every printing method requires specialized supplies, ranging from a whole array of unique dyes, rollers, squeegees, and screens for screen printing to a roll of HTV vinyl and a pair of scissors for the simplest at-home designs.

In general, commercial-level printing like DTG and sublimation printing require advanced technology and specific kinds of dyes. More artistic processes like HTV require smaller-scale supplies you could buy and use at home, like a Cricut.

Technology

Commercial printing methods like DTG and sublimation printing require advanced technology. That said, lots of methods work best if you can operate a graphic design program to create your own unique designs, so you can end up using advanced technology with almost any printing method!

Also, if you want to get more elaborate and complex, you can use more advanced technology with screen printing and HTV designs. Or you can keep things basic with just one screen and/or a Cricut at home, depending on how much technology you want to use!

Best Way to Print Cotton T-Shirts at Home

The best way to print cotton shirts at home is to use the heat transfer method with an inkjet printer or to cut out and use an HTV design. If you have a regular inkjet or laser printer in your home office, you can easily create any design and then use an iron or a small heat press to seal the transfer paper to your shirt.

Likewise, if you have a Cricut or even if you want to cut out a vinyl shape with a knife or scissors, you can easily seal the heat-activated adhesive onto a cotton shirt at home.

Cotton can handle high heat, so any method that uses a heat press or an iron does well on this kind of shirt.

If you want to get simple, you can use stencil and fabric dye or paint at home on a cotton shirt.

Which Type of Printing is Best for Polyester T-Shirts?

The best professional-level printing on polyester shirts uses the sublimation printing process, but you can also print on polyester at home using screen printing or other methods.

The thing to keep in mind with polyester is that it is sensitive to heat. You can use a heat press on it if you watch the temperature and timings, but it presents far more challenges than working with the more durable cotton.

What is the Most Durable Kind of T-Shirt Printing?

The most durable kinds of t-shirt printing are sublimation and screen printing, though several other methods will also last for quite a long time!

On the other side of that coin, you may find that DTG designs start to fade over time. Heat transfer designs can tend to crack or peel eventually. HTV designs will hold up quite well for a long time, but they may eventually begin to crack, as well.

How to Print on T-Shirts at Home

The easiest way for beginners to print on t-shirts at home is to try the heat transfer printing method. You do not need too many supplies, and you don’t need any experience at all!

Now, if you want to launch a home business selling t-shirts, you may want to consider learning more about screen printing or using HTV. Both of these methods can work well in a home studio without a lot of specialized equipment.

The other thing you usually want when you print on t-shirts at home is a low start-up cost. This rules out the giant commercial processes like DTG or sublimation printing! Instead, focus on more artistic and small-scale processes, like using vinyl cutouts or even airbrushing onto t-shirts.

Conclusion

Some of the most popular ways to print on t-shirts include DTG, sublimation, and screen printing. For easy DIY shirt printing, you may want to try HTV or heat transfer designs. Simple tools like a heat press make heat transfer or inkjet printing possible and make using heat transfer vinyl quite easy as well.

Some kinds of shirt printing like DTG and sublimation printing do need expensive professional equipment. But most methods do not need super expensive gear, including HTV designs, heat transfer printing, stenciling, and even airbrushing.