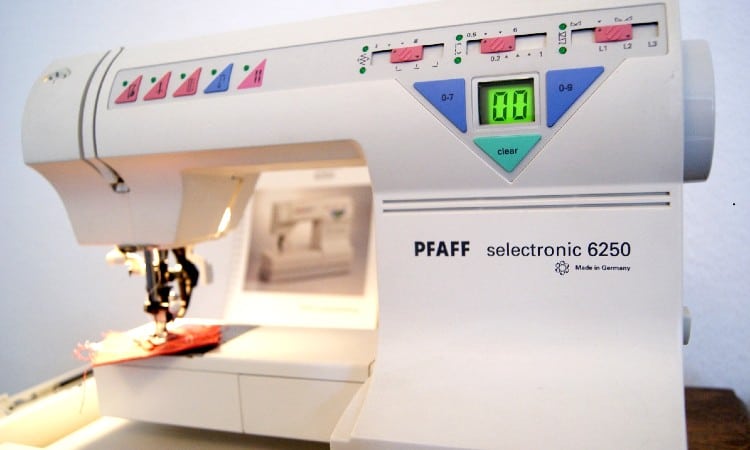

Pfaff sewing machines have ranked as some of the best machines in the world since back in the 1800s. But even these remarkable machines sometimes need troubleshooting! Next time your machine has trouble, you will want to know Pfaff sewing machine repair basics.

Pfaff sewing machine repair can involve simple cleaning, basic part replacement, and lubrication. Tension settings, jammed needles, and darning feet sometimes also need correction. Computerized machines sometimes have issues downloading new software as well.

In this article, you will find out what Pfaff sewing machines are and why they are so different. You will discover how to fix eight common repair issues and how to deal with vintage Pfaff repairs. Finally, you will get tips on finding a certified Pfaff dealer near you, too!

Source (1)

What Are Pfaff Sewing Machines?

Pfaff sewing machines have maintained an excellent reputation from the late 1800s until today. Modern Pfaff machines often come with highly advanced technology, including embroidery or quilting software. Many sewers still value vintage Pfaff machines built with precise engineering that they still run today!

Georg Pfaff founded this legendary German sewing machine company way back in 1862. He built the manufacturing company with such skill that it expanded from selling six sewing machines in its first year to selling 1,000 in its tenth year!

Like many inventors-turned-CEOs during the Industrial Revolution, Georg Pfaff and his team developed many technology innovations. That helped to make a name for the company. The stellar quality of Pfaff’s machines also made a big impact.

Pfaff remained a family company for almost a century. The 1960s saw the end of this era, though, as the company finally went public. In later years, the company that owns Singer bought Pfaff as well.

Today, the Pfaff brand still exists. But Pfaff as a company does not. It is owned by SVP Worldwide.

The good news is that you can still buy brand-new Pfaff sewing machines. At least, if you can afford them! These high-end machines often come with very high price tags.

Plenty of sewers claim that Pfaff makes the best sewing machines in the world. At any rate, they certainly offer stiff competition to other high-end sewing machine brands such as Bernina and Janome!

Pfaff Sewing Machine Troubleshooting: 8 Common Issues

Of course, as any sewer knows, all sewing machines will occasionally need troubleshooting, even fancy and high-quality Pfaff models. If you know what common issues to expect, though, you can prepare yourself to deal with the problems and move on.

Understanding basic sewing machine repair and troubleshooting before you find yourself caught in a giant tangle of thread and fabric will help you enjoy your peaceful sewing time. When you get a jam or a broken needle, you will simply remember how to fix the problem and then get back to sewing!

Check out these two quick words of warning before you dive in, though.

First, if you own a newer Pfaff sewing machine, it probably has a warranty. This means that Pfaff promises to fix the machine and supply replacement parts under certain conditions. You should read the warranty’s fine print and find out what you are allowed to DIY yourself and what kinds of issues you have to take into a certified technician to avoid voiding the warranty.

Secondly, please read your sewing machine manual before attempting a repair! Your owner’s manual will give you advice specific to the particular Pfaff model you own. Every model has its idiosyncrasies, so make sure you follow the guidance in your manual!

1. Sewing Machine Can’t Turn On

Nothing is worse than sitting down at your fancy sewing machine with your fabric in hand, only to discover that your machine will not turn on! This could indicate a serious wiring problem requiring professional attention. That said, you can also try a few simple solutions before you give up.

- Unplug the wall plug and try inserting it into another outlet. You may have blown a fuse, or the plug may have wiggled loose!

- Check the connection where the cord plugs into the sewing machine. This often comes loose, especially if you have used your machine for some heavy-duty sewing recently.

- Look at your machine carefully. Did it turn on, but the light didn’t come on? This could simply mean that you need to replace the tiny bulb in the overhead sewing light.

- If your machine turns on but will not sew or do anything, you might need to check the foot pedal. First, unplug the foot pedal cord and plug it back into the machine. If that fails, flip the pedal over and look for loose wires inside it.

2. Needle Stuck or Sewing Machine Jammed

One of the most common problems you run into while sewing is a stuck needle or jammed sewing machine. This issue can have multiple causes, so you may want to just go down this handy checklist until you get to the solution!

- The needle often refuses to go up and down when incorrect threading has created a giant tangle of thread beneath the fabric. To fix this, carefully remove the fabric and use scissors to cut away the thread tangle. Then rethread your machine after raising the presser foot and turning off the sewing machine for safety reasons!

- Sometimes the needle sticks or jams when it can’t get through the thickness of the material. Canvas, leather, upholstery fabric, and multiple layers of material in a collar or waistband often cause this issue! If this happens, you can try using a different type of needle, but you may also have too much fabric for your machine to handle.

- Another big cause of sewing machine jams is tension trouble. To find out more about fixing tension settings on your Pfaff machine, check out the section on “How Do You Fix Tension Issues” later in this article!

- Check your bobbin and make sure no loose thread or lint has jammed the works down there. To avoid this issue, you should always take out the bobbin case and re-insert it as you rethread your sewing machine!

3. Handwheel Jammed

The handwheel on your sewing machine looks like a large knob on the right end of your sewing machine. Turning this wheel manually raises the needle bar. Unless, of course, something has jammed the handwheel!

A handwheel that won’t turn often has the same causes as a general sewing machine jam discussed previously. The most common cause by far is a thread tangle caused by incorrect threading.

You may sometimes find other causes as well, though, including:

- Your sewing machine may have overheated. Pfaff sewing machines have powerful motors. Many new models have a built-in shutoff feature that allows the machine to refuse to sew if it reaches too hot a temperature inside. In this case, turn off your machine and let the poor thing have a rest!

- You probably take good care of your expensive Pfaff sewing machine, but just in case, give it a good cleaning! It’s always possible that lint buildup could have jammed a moving part.

- A broken belt could also keep the handwheel from working, In this case, the wheel may turn, but the needle won’t rise and fall. You can replace sewing machine belts yourself, but this is a fairly complex mechanical process. You may want to visit a repair shop and get some help!

4. Lubrication Problems

Some Pfaff sewing machines require regular lubricating with sewing machine oil to keep all the moving parts spinning smoothly. If your machine has not received this necessary lubrication, it may refuse to run or make loud grinding noises.

That said, please note that most new Pfaff models come with a self-lubricating ability and do not require oiling! Pfaff lists the current models that do need oil here, though you should always check your manual as well to find out if your model needs oil.

If you have an older machine or one of the new models that need lubrication, you should still follow the instructions in your manual to find out exactly what needs oil and how often you should apply the oil!

Follow these general guidelines to apply oil to your machine.

- Clean the machine thoroughly. It won’t do much good to drip oil on top of a layer of lint!

- Set up your work area by removing any fabric or thread that could get damaged and opening up the sewing machine as directed in your manual.

- Make sure your oil will work for your Pfaff machine. No matter what else you may read online, cooking oil, WD40, or car oil will not help your sewing machine! You need to use sewing machine oil that has just the right light consistency.

- Apply a small drop of oil to each area and allow it to soak in. You may need to stand ready with a clean rag to dab away any drips. If you can remove a part before oiling, such as the bobbin case, take it out so you can see what you’re doing!

- If possible, don’t get any oil on the needle, needle plate, or other areas that will touch fabric as you sew.

- When you finish, run a strip of cheap muslin through the machine and check if any oil stained the fabric. That way, you know it is safe to use your machine again!

5. Bobbin Won’t Turn

Mike Beer (2)

You can come up against multiple different types of bobbin issues that cause the bobbin to refuse to turn or seem to jam.

- Do you have the bobbin and bobbin case that came with your Pfaff machine? If not, you may have the wrong size or type of bobbin. Try purchasing authentic Pfaff bobbins, even though they cost a bit more!

- Another common cause of bobbin trouble comes from outside of the bobbin.! If you have a bent, dull, or broken needle, it may strike the wrong things as it comes down, causing a bobbin problem. Try replacing your needle before every new project or after every ten hours of sewing. Also, make sure you use the correct type of needle for your fabric, as a needle getting stuck in heavy fabric could also prevent the bobbin from turning.

- Likewise, while less likely, any dings or scratches in your bobbin can prevent a smooth rotation. Even Pfaff bobbins don’t cost that much, so just replace them if you have any doubts!

- Finally, you may need to adjust the bobbin tension. Try taking out the whole bobbin case, holding onto the thread tail, and dropping the case. If the thread unwinds smoothly, the tension is probably fine, but if it does not, you may need to adjust the screw on the bobbin case by minute increments to tighten or loosen the tension.

6. Foot Pedal Issues

Sometimes the sewing machine foot pedal that acts like the gas pedal in a car can run into issues like overheating or creating a burning odor. To troubleshoot your foot pedal, go through a few basic steps.

- Pick up the pedal and make sure you do not see loose wires inside. This does not happen super often, but you probably want to get expert help for any issues involving wiring!

- Try sewing for a few minutes and then pick up the pedal to find out if it feels warm to the touch. Your pedal can overheat from a couple of causes, including sewing too slowly for a long period of time or accidentally resting your foot on the pedal and causing it to almost turn on for long periods of time.

- If the pedal will only run super-fast and not at slow speeds, it has lost the ability to regulate the electrical current coming from your sewing machine. This is another visit-an-expert problem! (Unless you want to learn how to install a new electrical component in your pedal, in which case, go for it!)

- If the pedal makes a clicking or ticking noise, it may just need to settle into its paces. If the noise quickly goes away, don’t worry about it! If it continues, the insides of the pedal may have absorbed moisture and you may need to leave it in a dry place for a while.

7. Trouble Updating Pfaff Software

One of the biggest issues you may face while using a new Pfaff machine is learning how to install or update software. Pfaff’s newest sewing machines, as well as new quilting and embroidery machines, typically come with access to MySewNet, which is a way to register your software. This allows you to sign in and download updates when new features like a new embroidery hoop become available.

These fancy machines are run by computer programs that tell the machine and the needle how to make intricate embroidery designs, among many other tasks! But you know how your smartphone gives you alerts saying that it needs to update its IOS on occasion? These fancy computerized sewing machines need the same thing, sometimes!

Pfaff makes updating the software pretty easy once you have registered your purchased software and signed in to your MySewNet account. All you have to do is click on the Smart Update menu to get started.

That said, learning how to use and update software may present a steep learning curve for people more accustomed to mechanical sewing machines. You can always reach out to Pfaff’s customer service for assistance.

8. Difficulty with Darning Foot

Learning how to set up your Pfaff machine correctly when using the darning foot also presents a challenge. One of the cool things about many Pfaff models is their ability to allow free-motion sewing, which involves lowered feed dogs and special presser foot settings.

What is free-motion sewing or darning? It means you direct the motion of the fabric beneath the needle rather than allowing the feed dogs to pull the material through for you.

To set up your Pfaff machine for darning, you can insert the darning foot, but make sure you put the darning foot or presser foot in the special in-between setting as you raise the lever.

In regular sewing, you either have the presser foot fully lowered so that it holds down the fabric, or you raise it as high as it will go to give you lots of room to take the material in and out. Most Pfaff models also have a special mode in between those two extremes, and that is the place you want the darning foot to sit at for free-motion sewing.

Of course, you also need to disengage or drop the feed dogs as you begin this process. Refer to your manual for instructions on how to do this on your particular model.

Vintage Pfaff Sewing Machine Repair

Vintage Pfaff sewing machines require the kind of basic maintenance, oiling, and mechanical repairs you would find in any older sewing machine. That said, these vintage models remain extremely popular with sewers today because they are seriously heavy-duty machines! Many vintage Pfaff models were originally made and sold for the home business and domestic use.

Because of this, some of these vintage machines get classified as semi-industrial grade today. They can sew through multiple layers of canvas, leather, or upholstery fabric with no problem! They have powerful motors and heavy metal parts.

All of that goes to say that if you stumble across a vintage Pfaff machine for a reasonable price, snatch it up! If it seems cranky or broken, don’t give up on it. You can probably get it up and running again with a little TLC.

Check out these tips to help you repair and maintain your vintage Pfaff:

- Things like bobbins and presser feet have changed over time. Make sure you get vintage accessories that correctly fit your model. Your manual should list what style or “class” of bobbins and so on will fit your machine, but many online sewing groups will also provide helpful tips in this area.

- Keep a sharp eye on any wiring. Look for cracks in the plastic casing around the wires, and stop everything if you see a spark! Old wiring usually requires professional assistance.

- Clean it–a lot! All-metal sewing machines will likely need regular lubrication, and this does no good if you have not cleaned away any lint and dust first.

- When you do make repairs, use the tools that came with the machine, if possible. If not, look for a sewing machine repair kit or carefully match your screwdriver to the screws.

- Vintage machines often have bobbin winding assemblies that look quite different from the ones on modern machines! Refer to your manual and make sure you have all the pieces of this bobbin winder set up correctly.

- Another thing you may not know is that plugging in a vintage machine means it is turned on! Many vintage machines do not have a power switch like modern machines. This means you must always unplug your machine when you finish sewing.

How Do You Disassemble a Pfaff Sewing Machine?

Different Pfaff models have unique parts that require different disassembly, but most of the time, you can follow a certain sequence to take apart the outer casing of the sewing machine.

- Take pictures with your phone before you take anything apart. You may think you will remember what went where, but this little tip will save you a lot of hassle!

- Use the screwdriver that came with your machine (or a small eyeglass screwdriver) to undo the screws holding the top and front casing in place. Keep these screws carefully in a small baggy.

- Remove the front and top casing. In some models, the top casing, or the front casing over the arm, may lift on hinges.

- Gently turn over the machine and take out the screw in the center of the bottom.

- Now, look at the right side of the casing. If you pull down and towards you, this cover should come off over the handwheel.

- You can remove all the remaining screws from the bottom to take this casing off. This will allow you access to things like the drive belt and the motor, typically.

Your manual may or may not provide instructions regarding certain levels of disassembling. Remember that Pfaff wants you to bring your machine to their technicians for repairs rather than trying to DIY the repairs! This means the company may not have provided quite as much info on disassembly as you would like.

If you need a more visual guide, you can usually find a helpful fellow sewer on Youtube demonstrating how to dissemble your Pfaff model. Just make sure you plug in the model number to see a guide specific to your model.

How Do You Fix the Tension on a Pfaff Sewing Machine?

One of the most common issues you encounter while sewing is tension set incorrectly. This can cause your stitching to bunch up, skip stitches, or even create a tangle of thread beneath the fabric!

You’re probably tired of hearing this by now, but as always, you should refer to your manual for specific instructions on tension adjustment. Also, some computerized models allow you to make tension adjustments through the touchscreen, though the basic concept of raising or lowering the tension numbers remains the same.

To adjust the upper tension on your sewing machine:

- Always rethread the machine as a first resort! Also, make sure you raise the presser foot before threading your sewing machine. If the presser foot is lowered, the thread cannot slide between the tension discs correctly.

- Set the upper tension to 4 or 5, the standard tension settings. If you see loops or knots of thread on the top of the fabric, or if the stitches pucker up while sewing on the normal setting, you need looser tension. If you get tangled thread or odd stitches on the underside of the fabric, you need tighter tension!

- You should also know that many kinds of sewing require specialized tension settings. For instance, topstitching may need different tension settings than inserting a zipper. Obviously, every type of fabric will also react differently and will require unique tension settings, as well!

Pfaff Sewing Machine Repair Manual

Your Pfaff sewing machine manual provides crucial information on how to set up, clean, and repair your machine. No matter what kind of sewing machine you own, you should read the manual before trying to use it!

This is especially true for a computerized machine. You will need the manual to learn how to use the touchscreen or LCD panel, how to install software and many other computerized tasks.

If you have a new Pfaff machine, it came with this important pamphlet. If you bought a used Pfaff machine, you might be able to reach out to Pfaff customer support for help. That said, the company usually only provides fairly current manuals.

If you have a vintage Pfaff, you probably need to purchase a manual on Etsy or eBay or join a sewing forum online to see if anyone there has your Pfaff model and can share the manual with you.

Pfaff Sewing Machine Repair Parts

Finding replacement parts or accessories for a new Pfaff machine is a breeze. Simply visit your local dealer, take a look at Pfaff’s website, or try out a third-party seller like sewingpartsonline.com. The prevalence of this brand makes it easy to find whatever you need!

If you have a vintage Pfaff sewing machine, you will probably have better luck searching Etsy or eBay for the part you need. Just make sure you plug in the specific model of your Pfaff machine to find exactly the right part!

Pfaff Sewing Machine Dealers Near Me

Pfaff sewing machines have such a great reputation and remain so popular today that finding a local Pfaff dealer is quite easy. You can go to these dealers to find certified technicians to repair a machine still under warranty or purchase a new Pfaff sewing machine!

Simply visit Pfaff’s website here, type in your zip code, and check out the list of dealers near you.

As a word of warning, though, you do need to find a Pfaff-certified repair person if you have a warranty. If you do not have a warranty on your machine, you have a bit more freedom to simply visit your local sewing repair shop.

How Much Does it Cost to Service a Pfaff Sewing Machine?

Most certified Pfaff repair shops will charge an average of at least $100 just to examine your sewing machine. Modern Pfaff machines have fancy computers and complex parts, so you can understand why trained technicians charge a lot to service them!

On top of that, you typically have to pay for any necessary replacement parts yourself. Also, some technicians charge by the type of repair, but many charge by the hour, much like a mechanic working on your car.

Alternatively, you can learn enough about your Pfaff to make most repairs yourself. You will still have to purchase any necessary replacement parts. You may also want to spend a significant amount of time researching or even taking online classes before attempting this.

Is it worthwhile to spend all this money getting your Pfaff repaired? At least nine times out of ten, yes! Pfaff machines cost a lot and you do not want to discard that costly machine because of a couple-hundred-dollar repair fee.

There are some exceptions to this rule, though. Mechanical Pfaff machines will run forever. Like, literally for decades and decades! It’s pretty much always worth getting necessary repairs on a mechanical or vintage Pfaff model.

Computerized machines may or may not have long lives. As technology develops so rapidly, some computerized models quickly become extinct, like the older Pfaff machines that ran off a floppy disc. You probably don’t want to pay for repairs on that particular model!

Conclusion

Pfaff sewing machines offer advanced technology and a huge range of sewing functions. Though Pfaff sewing machines have an excellent reputation, they sometimes require troubleshooting, such as correcting tension settings. Other common issues include jammed needles or stuck handwheels.

New, computerized Pfaff models may need regular software updates. They might also need troubleshooting of the darning foot and free-motion sewing feature. Vintage machines need regular care and oiling to function at full capacity.

Do you have a Pfaff machine? What do you like to sew with it? Leave a comment below to let us know!

(1) Shared under a Creative Commons (BY-SA) license

(2) Mike Beer, CC BY-SA 4.0 , via Wikimedia Commons