When you start printing t-shirts, you have to select the printing method you want to use. Screen printing and digital printing both offer popular ways to print cool shirts. When you compare screen printing vs digital printing, what exactly is the difference?

Screen printing and digital printing use different processes to apply ink to t-shirts. Screen printing uses stencil screens to layer plastisol ink one color at a time onto fabric. Digital printing uses large printers to apply ink onto the fabric in complex designs.

In this article, you will learn how screen printing and digital printing work. You will discover key differences between these methods, like cost and complexity. Finally, you will find out how these printing methods compare to using vinyl and a heat press.

Quick Navigation

- What is Screen Printing T-Shirts?

- What is Digital Printing on Shirts?

- Screen Printing vs Digital Printing: Key Points

- What is the Difference Between Screen Printing and Digital Printing?

- Silkscreen vs Screen Printing

- Screen Printing vs Sublimation

- Vinyl Printing vs Digital Printing

- Screen Printing vs Digital Printing vs Heat Press

- DTG vs Screen Printing: Which to Choose?

What is Screen Printing T-Shirts?

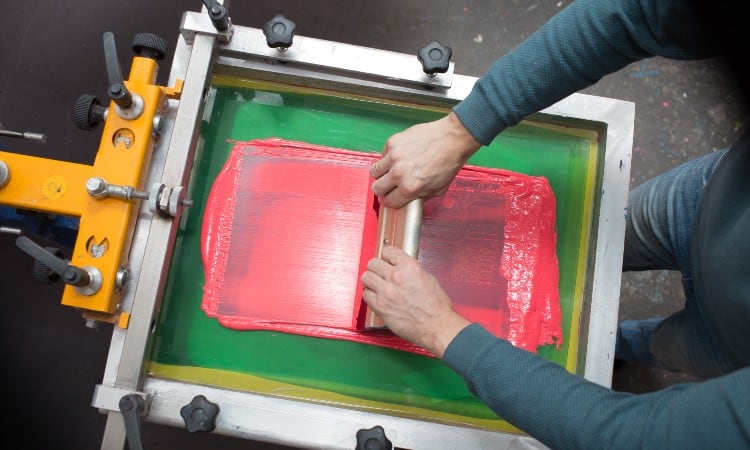

Screen printing applies thick ink onto fabric through a negative of the design or through a stencil placed on a mesh screen. This creates a thick, soft layer of ink on the t-shirt. This process typically uses just two or three ink colors, as the printer has to apply each color in a separate layer, using a separate screen.

The basic process of screen printing involves preparing the negative space on the screen and then smoothing ink over that stencil. The printer then applies the screen to the fabric. After this, the inked design usually requires heat setting or curing.

You may also see this process called silk screening because it is a quite ancient art form first perfected in Chinese culture thousands of years ago. Back then, artists used silk screens to apply the stenciled layers of ink. Today, commercial shirt printers mostly use polyester mesh screens and viscous plastisol ink.

The special ink used for modern screen printing does not soak into the fabric of a shirt. It rests in a nice soft, durable layer on top of the fabric, creating a unique raised design.

At its most basic form, you can create screen-printed designs using a hand-cut stencil, a wooden frame with mesh stretched over it, and some plastisol ink. Many home-business t-shirt printers use some variation of that simple method. On the other hand, commercial screen printers use giant contraptions that can hold up to ten or twelve screens at a time to efficiently layer multiple colors onto the design.

The negative or stencil used on the screens can also vary a lot in complexity. If you plan to screen print at home or for a small home business, you can create your stencil that outlines the negative space by using a Cricut or something similar. More advanced screen printing uses a chemical process that works a lot like old-fashioned photo development to create a chemical stencil on the screen, allowing the ink to push through in the positive space of the design.

What is Digital Printing on Shirts?

Digital printing, also called DTG or direct-to-garment printing, applies a printed design directly onto the fabric. This process works pretty much the way your home office printer applies ink to paper! This method is pretty new in the clothing industry but has quickly gained popularity because of how little time it takes.

DTG uses the basic four primary colors that most paper printers use: magenta, cyan, yellow, and black. Sometimes DTG printers come in six colors and include red and green in that spectrum.

The basic concept, though, is that the printer mixes these primary colors to create any image or photo you want, just like a paper printer printing out photos and images! You can think of this process as the printer spraying ink straight onto the fabric.

That said, DTG printers are pretty enormous–they have to easily slide one or more shirts through instead of a small piece of paper! They also use quite advanced technology. For these reasons, this kind of direct-to-fabric printer can cost anywhere from $15,000 to hundreds of thousands of dollars.

Commercial printers are often willing to make this massive investment because DTG printing is so quick and easy. Plus, it allows for flexible and intricate designs that involve many colors or gradients of colors.

This kind of printed design usually has a soft, flexible feel on the fabric. It does not create a raised design like screen printing because it uses a type of ink that soaks into the fabric, but it also has a more lightweight feel that you may like better.

DTG designs may have a more muted and less vibrant quality in the long term. The trade-off for this is the ability to offer much more complex designs and to print shirts super quickly.

Screen Printing vs Digital Printing: Key Points

Before you dive off the deep end and examine all the ins and outs of each type of printing, take a moment to get a quick overview of the basic pros and cons of DTG and screen printing.

| Screen Printing | Digital Printing | |

|---|---|---|

| Durability | More durable because of thick ink used | Slightly less durable but will hold up for years with proper care |

| Quality | Usually viewed as the highest quality printing method | Slightly lower quality because of less vibrant colors |

| Complexity | Works best with one, two, or three ink colors and a less complex design | Can easily create very complex designs such as photos or memes |

| Consistency | Slightly less consistent because of necessary human involvement in set up | Highly consisted because the printing process is run by a computer |

| Cost Efficiency | Cost-efficient for large orders | Cost-efficient for small orders such as custom-tees |

| Multi-Color Prints | Commercial screen printing machines can use multiple colors, but not as easily as DTG | Easily creates multi-color prints quickly and efficiently |

| Color Blending | Very poor, as every screen can only layer one color at a time | Excellent. A DTG printer mixes primary colors into any shade or gradient and can create complex images using these blended colors |

| Set-Up Time and Cost | Requires a lot of setup time and expensive materials | Requires little setup time but expensive printer |

| Quantity | Can easily print large batches of the same design | Can print large or small batches with no impact to the bottom line |

| Best Fabric | Can print well on cotton or polyester | Only works well on 100% cotton |

| Special Effects | Special inks such as glitter inks can create all kinds of special effects | DTG does not give the option for special effects |

| Best for | Large orders, less complex designs, athletic wear, or vintage/special effect designs | Custom orders, complex images, softer and more breathable designs |

| Average Cost Per Shirt | About $5-9 to print. Sells for $10-25 | Less than a dollar to print. Sells for $10-25 |

What is the Difference Between Screen Printing and Digital Printing?

The biggest difference between screen printing and digital printing is in the method used to apply ink to the fabric. Screen printing uses a process that pushes ink through a stencil onto the fabric one color at a time. Digital printing uses large printers that squirt computer-mixed ink onto the fabric in complex patterns.

The differences don’t end there, though. Each printing method has its own strengths and weaknesses. For example, DTG offers more color choices, but screen printing can incorporate all kinds of special effects like using glitter ink!

Durability

Which lasts longer, screen printing or digital printing? Screen printing wins in this category hands-down. The process of screen printing bonds the thick layer of ink with the fabric through a heat curing method. Screen-printed designs should maintain their shape and color for many years.

Does digital printing fade? DTG designs use a different, thinner type of ink. These images will begin to fade after several dozen washes.

That said, a low-quality DTG print may look washed out very quickly. Likewise, if the plastisol ink used in screen printing does not cure properly, these designs can crack and peel away from the fabric. It all comes down to the quality of the printing process.

Quality

In general, screen printing is seen as higher-quality because it has more vibrant designs and can last longer. That said, DTG offers better color blending and more complexity of design, so you could argue that this newer printing method has more to offer than screen printing.

Why does screen printing offer more vivid designs? The difference lies in the kind of ink used. Screen printing uses plastisol ink, which is an opaque, thick substance made of PVC particles in a special emulsion.

Most of the time artists will lay down a layer of solid white plastisol before printing color layers on top. This allows the colors to pop very vividly.

DTG looks less bright because it uses water-based inks and won’t show up as well on dark fabrics. This is because the thin, water-based inks end up looking partially transparent.

Both printing methods come with pros and cons when you get right down to them. But the raised design and bold colors in a screen-printed design often look classier and more expensive than the slightly more muted color and flat design created by DTG printing.

Complexity

DTG printing easily accommodates complex designs such as photos or full-color illustrations. Screen printing can create complex designs by layering many colors on top of each other, but setting up a complex screen print takes a lot of time and work.

One of the reasons DTG wins out in this category is its ability to print fine, clear detail. DTG can print tiny text just like your home printer can print small fonts onto paper. It can handle varying shades like curlicues of smoke or a print of lace or feathers.

Screen printing can create complex designs, but it does not handle tiny detail. For instance, you might have to make a larger lace pattern so that the thick, raised ink does not smudge together and fill in the tiny holes in the lace design.

Another key factor in the complexity of the designs is something called halftones. These are tiny dots used to indicate gradients of color in an image. DTG uses such tiny halftones that you cannot see the dots without a magnifying lens of some kind, but screen printing has to use much larger dots that you can see clearly in the design.

Consistency

Most of the time, it’s easier to create consistent designs using DTG printing because you have a computer running the same graphic through the printer again and again. For screen printing, you need a human being to set up the screens frequently. This can lead to slight discrepancies from one batch of printings to another.

For instance, if the artist pulls the mesh screen a fraction more tightly over the frame in the first printing and a fraction more loosely in the second printing, you may find some discrepancies in the accuracy of the screen print designs.

Cost Efficiency

Which is more expensive, screen printing or digital printing? This depends on the number of prints you want and the complexity of the printed design.

DTG printing can print small orders, or even just one design, quite efficiently. Screen printing, in contrast, requires a lot of set-up time to prep screens and create the stencils or negatives for each color layer.

Screen printing can make a large order very cost-effectively, though, because you only have to do all that set up one time for the whole batch of shirts.

DTG can handle complex designs just as cheaply as simple designs, but added complexity makes screen printing cost more. If you use just one color for a print, you only need to set up one mesh screen and one set of negatives for screen printing–but if you use many colors, you have to prep many screens!

Multi-Color Prints

Digital printing easily creates multi-color prints by using a computer program to mix the CMYB primary colors. Screen printing works most easily for just one, two, or three-color designs.

That said, you can create multi-color prints using screen printing. This raises the cost significantly because it means prepping and using many more screens to apply each layer of color.

Color Blending

Color blending is mixing colors to create unique shades of those colors and smoothly applying gradients of saturation. In DTG printing, this is done by applying thousands of tiny dots of the colors to make varying gradients of color saturation. Plus, this kind of printing easily merges and overlaps colors and shades.

Color blending is one of the big reasons DTG printing shines at creating complex images! Think about a black-and-white image of a face–you have to use many different shades of white, black, and grey to create the angles and shadows of the face!

Screen printing usually does not attempt color blending. Remember, this process works by laying one color screen on the fabric at a time.

Set-Up Time and Cost

Digitally printed shirts do require some setup and a great deal of expertise. You have to know how to send the digital file to the printer and how to load the shirts into the very large commercial printers, for example.

But screenprinting takes much more set-up time. Screenprinted shirts usually cost much less when you order them in bulk because of this. You may see a set-up fee or a processing fee if you order screen-printed shirts because of this, too.

Quantity

Screen printing large amounts of the same design will cost less than digital printing the same amount of shirts with the same design. However, small orders of screen print designs can cost a lot.

This is because you have to put in a lot of work setting up for a screen print design, but you’re good to go once you have done that!

Best Fabric

Both screen printing and DTG work most easily on 100% cotton fabric. That said, you can safely and effectively screen print onto polyester if you make a few adjustments to the process. DTG printing only works on cotton.

For this reason, if you want to buy a bunch of custom-printed shirts, you should not use a company that offers digital designs printed onto polyester shirts! You will end up with quickly fading prints.

Also, if you want custom-printed athletic wear, such as jerseys for a basketball team, you should use screen printing. Screen printing can bond with moisture-wicking athletic fabrics, while DTG designs cannot.

Special Effects

DTG printing does not offer special effects, but screen printing has all kinds of unique effects you can employ!

For example, you can create a screen print using raised puff paint. Or you can use special glitter, metallic, or glow-in-the-dark ink! Another popular effect screenprint artists like to use is to create images or letting using flashy fluorescent colors, known as “dayglo” shades.

You can also use plastisol inks that have a suede-like texture. Or you can make a 3D design by layering high-density inks. You can even create a crackle effect if you like a distressed, vintage look!

Best For

Screen print designs work best when you want a large order of the same design because the printer can just reuse the color screens over and over without setting up the print again. This printing method also gives you the most durable and vivid print on a shirt. The raised ink and bright colors also make these designs look very nice.

DTG works well for custom prints because you can do just one print with no hassle since all you have to do is send a computer file over to the printer! This printing method creates detailed, complex images easily. It also makes a lighter and softer print that feels flexible and breathable, so you may want to choose DTG if you prefer comfort over long-lasting designs.

Average Cost Per T-Shirt

It usually costs about $5-$9 to screen print a shirt, though the cost decreases a lot for a bulk order where you can repeatedly print the same design. The cost to purchase a screen print tee can vary a huge amount, often falling between $10-$25.

DTG shirts don’t cost much to print–you can typically print one for less than a dollar! Buying a digitally printed shirt usually costs less, but of course, this depends on factors like the company selling the shirt and the venue, and so on. The average price still falls between $10-$25.

Silkscreen vs Screen Printing

Silkscreen printing and screen printing are two different names for the same process. These days, you see the term screen printing much more often, especially by commercial printers. But some artists still call their work silk screening.

The name “silk screening” originated thousands of years ago because artists used screens made out of fine silk to apply ink to parchment, paper, or silk banners.

Today, pretty much everyone uses polyester mesh screens because they cost so much less.

Screen Printing vs Sublimation

Sublimation printing uses heat and pressure to turn ink particles from liquid to gas and then bond those particles with the solid surface of a shirt, mug, or baseball cap.

Like screen printing, you have to use a special kind of ink for this process. You also need a sublimation printer that can print onto a special transfer paper. Finally, you use a heat press to seal the design onto the shirt (or other items).

Sublimation printing has seen growing popularity in recent years because it creates high-quality, permanent designs. The liquid-to-gas process causes the dye particles to bond deep within the fabric fibers, meaning that the design should last as long as the fabric of the shirt!

This process also has some of the advantages of DTG printing–you can easily create complex, multi-colored designs by sending a digital file to the sublimation printer.

On the other hand, screen printing still wins for appearance and special effects. Sublimation printing will not look as vivid, and you can’t print with glitter ink using a sublimation printer–at least, not yet!

Vinyl Printing vs Digital Printing

Vinyl printing uses special printers to print designs directly on heat-activated vinyl. The vinyl then gets cut out and applied to the fabric using heat.

Vinyl prints have extremely good durability. This is the kind of process used to make car wraps or dishwasher-safe mugs and tumblers. You can make quite complex and multi-color designs using this process as well because you use a digital file sent to a printer to create the image.

DTG printing does not hold up as well as print on vinyl. However, it does cost less. It also has a softer and more comfortable feel because it applies ink directly to the fabric and does not have a layer of plastic on top of the shirt.

Screen Printing vs Digital Printing vs Heat Press

Screen printing, digital printing, and heat press printing are the most popular ways to create custom t-shirts, but every method has pros and cons.

You can use a heat press on a shirt in two different ways. First, you can use HTV or heat transfer vinyl. You simply send a digital file to a Cricut or electronic cutting machine and then use the heat press to adhere your vinyl shapes to the fabric.

Second, you can create a digital print on vinyl or transfer paper and then use a heat press to seal the design onto the shirt.

Using vinyl cut-outs has a lot of advantages, such as simplicity, low cost, and relatively good durability. Using digital prints on vinyl or transfer paper also has some advantages. You can create elaborate, complex designs for a relatively low cost.

Then again, DTG allows you to print large or small orders cost-effectively. It can also run simple or complex designs with little variation in cost. The only downside is that even good quality DTG prints will not hold up as long as some other printing methods, and it does not produce quite such vivid colors.

Screen printing remains the favorite for high-quality prints, but it is much cheaper when you use only a few colors. It also gets cheaper with larger orders and may cost a lot for just one or two custom prints.

DTG vs Screen Printing: Which to Choose?

Digital printing and screen printing can both create lovely prints, but each method can work better in certain circumstances.

Pros of DTG printing:

- Easily creates multi-colored, detailed designs, allowing for great complexity.

- Handles small orders in a cost-effective way

- Uses water-based ink that soaks into the fabric, leaving it feeling soft and breathable

- Not as durable as some methods, though it should last for dozens of washes

- Has good color saturation but does not stand out well from dark-colored fabric

- Does not look quite as vivid or bright

- Can only work well on 100% cotton

- Creates raised designs that have excellent durability

- Uses plastisol ink which has vivid, bright colors and can provide many special effects such as metallic ink or glitter ink

- Can adhere to cotton or polyester

- Can create bulk orders of the same design cheaply

- Requires a lot of setup for each print

- Multi-colored designs need additional color screens, which add to the time required and the cost per shirt

- Complex, detailed designs are possible but take a lot of work