Do you have brilliant ideas for the perfect cool or funny custom ink design for a t-shirt? Whether you want to buy a custom shirt or make your own, you may find all the variations in price confusing. So, how much does a custom t-shirt cost?

Custom t-shirt prices vary greatly depending on the printing technology used, the material of the shirt, and the number of shirts in print run. Bulk orders often cost much less to manufacture than one or two shirts. The type of shipping used can also impact the cost of custom t-shirts.

In this article, you will learn all about the key factors that can impact the cost of a custom t-shirt. You will discover tips for pricing different kinds of shirts, like sublimation vs screen prints. Finally, you will find out how t-shirt businesses turn a profit by making custom shirts.

What is a Custom T-Shirt?

A custom t-shirt has a unique design, either created by the artist/printer or designed by the customer. The main difference between custom shirts and the tees you buy off the shelf in a big box store is that custom shirts have a specific intended audience and typically come in small orders rather than in bulk mass-produced amounts like the clothes you can buy in Walmart.

Most often, the term “custom shirt” means that you can design the image you want. You then submit the design to a company or artist who handles the printing for you. This is a great way to get a specialty shirt without buying pricey printing equipment and learning how to work it yourself.

Custom shirts usually involve a transaction between a specific customer and an artist. Either the customer requisitions something the artist creates just for that customer, or the customer makes a design and asks the artist to print it.

But in a broader sense, custom shirts can also refer to any printed shirt designed by a small-scale printer. For example, if you search online t-shirt stores, you will see a lot of stores promoting “custom shirts” that they have already designed and plan to sell to more than one customer.

Whether you submit the design yourself or ask an artist to create it for you, the actual printing can happen in many different ways. In the next section, you can find out how printing a custom t-shirt via screen printing, sublimation, DTG, or vinyl can impact the cost.

How Much Does a Custom T-Shirt Cost?

Custom t-shirt prices range from as little as $2 or $3 to as much as $30. This large variation in price occurs because so many factors can impact how much it costs to produce a custom tee. These include the type of printing method used, the number of shirts ordered at once, and the kind of shipping used.

The general rule of thumb for most t-shirt printers is to add at least 40% of the total production cost of the shirt onto the retail price. So if it costs a printer $15 to make a shirt, she will charge roughly $21 to the person buying the tee.

This sounds reasonable and simple. The catch is that every different printing method involves different cost factors, so there is no standard price for production from one printer to another.

That said, all printers use the same basic equation of cost of materials + cost of labor + overhead X desired profit percentage.

Suppose the materials, including the blank shirt and ink or vinyl, cost the printer $5. Add that to the cost of labor to prep, print, and heat press the tee. Depending on how long this takes, you may add a couple of dollars per item for the labor cost, bringing you to a total of about $7.

Finally, you want to add a small amount for overhead items like the rent on your shop or the electric bill, bringing you to about $8 in total cost to make the shirt.

But of course, you want to turn a profit! So you multiply the profit percentage you want to see by one plus the profit percentage you want. If you want to see a 50% profit percentage, use this equation: 8 X (1 + .5). Using this equation, you would charge your customers $12 per shirt.

Vinyl Shirts

Custom vinyl shirts typically cost around $20-$30. They have a fairly high production cost because they take a lot of time to make.

Vinyl shirts feature designs made out of heat transfer vinyl or HTV. This method of decorating custom t-shirts creates a soft, raised design on the surface of the shirt that looks classy. It is a popular way for small-scale printers to get started because it uses less expensive equipment than many other types of printing tees.

To make a vinyl shirt, the artist sends a digital cut file to an electronic cutting machine. The machine cuts out the outline of a shape in a sheet of HTV. The artist then removes the negative-spae vinyl, leaving only the design to place on the shirt.

Finally, the artist uses a heat press to activate the adhesive on the back of the vinyl design, permanently fixing it to the fabric of the shirt.

Vinyl shirts have some unique costs to the printer.

- It takes time to weed the vinyl image or lettering out of the sheet after a machine cuts out the shape. This means that every single shirt made with a vinyl design will take the same amount of prep time for the printer. This also means that the artist needs to factor his or her time into the cost of the shirt.

- Different types of HTV have different price points. Special effects like glitter HTV or neon HTV will cost more than regular matte HTV.

- If the design uses more than one color, the artist has to cut out each color separately from its own sheet of vinyl. This means that multi-color vinyl designs require more time and effort for the artist than single-color designs.

These factors impact the retail price the consumer will pay for the shirt.

- Vinyl shirts do not usually get cheaper when ordered in bulk. This is because the printer has to put the same amount of labor into each garment, no matter how many you order.

- Basic HTV with a soft matte finish will cost you less than adding in special effects like glitter.

- Ordering a single-color vinyl design will cost less than ordering a design with two or more colors.

Screen Prints

Custom screen print t-shirts usually cost between $20 to $50, depending on the complexity of the design.

Screen printing involves creating a stencil of the image on a mesh screen. The printer then pushes a thick, soft ink through the stenciled screen to form the design on the shirt. Making stenciled screens takes a lot of time and effort, but the printer can reuse the same screens many times, making additional shirts cheaper and cheaper in terms of labor cost.

Of course, screen print shirts do have unique costs for the printer.

- Making stenciled screens involves a complex process of exposing a chemical emulsion to intense light to develop a negative of the image. This means prepping screens for just one design may take a day or more. For this reason, screen printing does not make sense for just one or two customer shirts–it works better for people who want to bulk order ten, twenty, or more shirts with the same custom design.

- A printer can only apply one layer of ink through a screen at a time. This means the artist must make separate stencils for each color in a multi-color design and then layer the ink on one screen at a time. Because of this, single-color shirts colts less to produce than multi-color shirts.

- Screen printing works best on cotton t-shirts. Cotton costs more than polyester, so the printer has to calculate the cost of a good-quality blank shirt into the final retail price.

Naturally, these special costs to the printer translate into additional costs to the customer.

- You can buy large-scale orders of screen print shirts at a much lower cost per shirt than small orders. This is because the labor cost decreases exponentially with larger orders, as the printer can keep reusing the same screens to make more and more shirts.

- You can buy single-color screen print designs much more cheaply than multi-color designs. Some printers break it down as simple as $20 for a one-color design and $55 for a five-color design!

- While you get a softer, better-quality shirt when you order a cotton screen-printed tee, you have to pay for that quality.

Sublimation Prints

Custom t-shirts made using sublimation printing often cost $10-$15. This much lower price point stems from the fact that sublimation works on cheaper polyester fabric. The exception here is all-over sublimated shirts, which typically cost more like $30-$45 as they use larger equipment and a more complex process.

Sublimation printing uses a unique type of ink that turns into a gas when exposed to high heat. The gaseous particles of ink travel deep into the fibers inside polyester fabric. When the ink cools, it returns to a solid state without becoming liquid first.

This interesting process, called sublimation, gives this new printing method incredible durability. Sublimation designs will last without fading or cracking for many years.

To create the print, the printer uses a special printer loaded with disperse dyes and prints the image onto a piece of transfer paper. Then the printer uses a heat press to apply the heat to transfer the dye from the paper to the polyester fabric.

- One of the big advantages of this method for a sublimation printer is that this method only works on polyester fabric. This means the printer can buy low-cost polyester blank shirts and save a lot of supply overhead. Some printers who work with big orders can get the cost per shirt down to thirty cents!

- On the other hand, sublimation dyes cost more than many other types of shirt printing dyes, so the printer does have to invest here.

- Sublimation prints made using a small letter-sized printer cost much less than all-over sublimation on a garment, which requires different equipment. This means that different kinds of sublimation projects can cost the printer more or less to produce.

This means that sublimated tees can have variations in price for the customer.

- Most of the time, sublimated prints cost much less than many other types of custom tees because they use polyester shirts. As a customer, this means you have to buy a shirt that uses high-quality fabric, but you also get it a lot cheaper!

- Sublimated prints will hold up longer than many other styles of custom t-shirts, so customers get extra durability as an advantage.

- Cheaper sublimated designs have a fairly small shape, no large than the size of letter-sized paper because sublimation designs print onto the transfer paper first and then adhere to the shirt using heat. This does mean some limitations in the style of design available unless the customer wants a shirt printed all over with a sublimated design using more expensive equipment.

DTG Prints

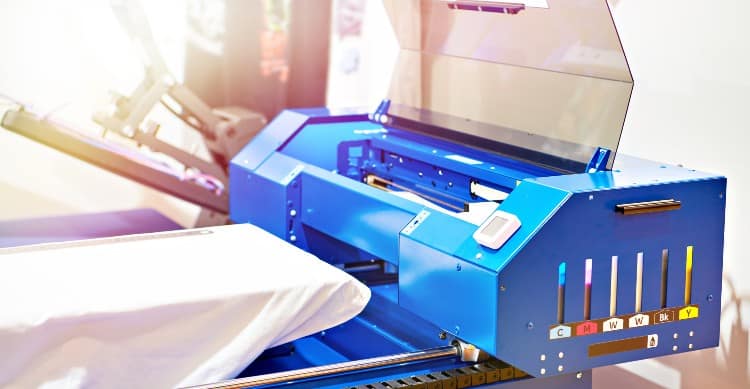

Custom t-shirts made using DTG or direct-to-garment printing cost anywhere from $10 to $50. The big price range depends on the darkness of ink used on the shirt, as extra layers of ink cost the printer a lot of money. Also, DTG printers cost thousands of dollars, so the overhead cost for each garment goes up unless the printer has already paid off the initial startup cost.

DTG printers apply a design right onto the fabric by using large commercial printers. The printer creates or edits a digital image and then sends it to the digital printer. Finally, the shirt goes through a heating process to cure the ink.

It takes two to three minutes for an expert printer to run off each print. This means there are no cost savings for bulk orders, as every individual shirt requires the same time.

Most DTG shirts have the lowest price of any custom-order tee. They also don’t have great quality and can tend to fade over time because they use water-based inks.

- The printer has to pay for ink, which can cost as much as $8 per shirt in extreme cases (more often, it only costs about twenty cents per shirt, though). This means that more complex designs- especially bold, dark inks- will cost more to make.

- DTG works best on cotton shirts, so the printer must factor in the cost of the blank t-shirts.

- The printer can easily make just one or two copies of the same shirt design without losing money, which is a great way to reach a market of people who just want one shirt made out of a custom design.

So, what does this mean for the customer?

- DTG offers lower pricing for small orders than many other types of custom tees.

- That said, DTG does require a lot of labor to run shirts through the printers and heat set them.

- Also, good DTG prints use cotton shirts, which will cost you a bit more since it costs the printer more to buy blank cotton shirts.

By Number of Shirts

Another good way to approach the cost of a custom t-shirt is to look at how much a shirt costs based on the number of shirts in your order.

- For vinyl shirts, large orders do not save the printer anything. It still requires the same amount of time to weed out the excess vinyl from a cut and apply the design by hand to each garment.

- For screen printing, the labor cost goes down exponentially for larger orders. This means that you can buy 50 screen-printed shirts much cheaper per item than you can buy five!

- For sublimation prints, bulk orders often come a little cheaper because repeating the same design over and over allows the printer to work efficiently and save a bit on labor costs. However, she still has to print out each transfer paper and use a heat press to sublimate the dye onto the shirt by hand.

- DTG custom shirts work best for small-scale orders. It does not take less labor to make a big order, meaning that the cost does not go down much for the consumer when placing a bulk order.

Shipping Options

Shipping options can also dramatically impact the cost of custom t-shirts, both for the printer and the consumer.

One of the big reasons that apparel costs overall have increased by as much as 5% in recent years is that the cost of gas keeps rising. This impacts the printer, who has to have blank shirts shipped in bulk from other parts of the world before creating custom tees.

It also impacts the cost of shipping to the consumer. Because of this, many printers will jack up the price of a tee to still provide a “free shipping” option without selling the shirt without making a profit.

Of course, bulk orders cost more to ship than a single shirt. Even with small orders, factors like the size of a package will also impact the cost of shipping.

How Much Does it Cost to Make a T-Shirt?

On average, it costs $7-$8 to make a custom t-shirt, though, of course, this varies based on the type of design and printing method used. It may cost closer to $10-$15 to produce certain types of prints.

Check out this list to see how much it costs, on average, to print just one shirt using each of the printing methods described in this article versus a large order.

One Custom T-Shirt

If you only want one custom t-shirt, your best bet is to order one from a DTG printing company or an HTV vinyl t-shirt artist.

- It typically costs about $10 to make a custom vinyl shirt. This can vary a lot depending on the complexity of the design, as it takes the artist time to weed more complicated images.

- It is not cost-effective to make just one screen print shirt. It takes too many hours to prep the screens.

- A printer spends an average of $7 to produce a custom sublimation print t-shirt.

- It costs roughly $14 to produce a DTG custom tee in the United States. In some cases, producing the same shirt oversee may cost less than half that price, though.

In Bulk

For some t-shirt printing methods like screen printing, bulk orders give you a much lower price per garment because it costs the printer much less labor per shirt.

- Generally speaking, vinyl shirts do not cost any less to produce in bulk. The artist has to spend the same amount of time cutting out the vinyl shapes or letters for each shirt.

- Screen printing costs the printer far less with bulk orders. This is because screen printing has a labor-intensive setup but requires only thirty seconds or so to print each shirt copy. A printer could make 500 copies of the same shirt and the cost to produce each one would go down to less than a dollar!

- Sublimation printing will cost the printer the same amount to produce in bulk per shirt as it does to make a single print. The only potential cost savings here would be if the printer can get a better deal by placing a bulk order on blank tees before beginning printing.

- DTG printing does not cost the printer less for bulk orders. But printers often provide customers a discount for bulk orders, just because the printer can make so much money off large orders.

Average Price for a Custom Print T-Shirt

The average price for a custom t-shirt is $25. But this means very little to you as a consumer because every printer, style of design, and type of shirt will cost you a different amount. The actual range of prices for a custom tee falls between $10-$55 from most printers.

If you plan to print shirts yourself, keep in mind that many different factors will impact how much it costs you to produce a custom shirt. These include the type of shirt, the printing method, the complexity of the design, and the number of items in the order, among others.

T-Shirt Pricing Calculator

If figuring out the price of every kind of custom shirt on a case-by-case basis seems overwhelming, try using a free online t-shirt price calculator! These work based on averages, but they can give you a good estimate of what to expect.

How Much Does it Cost to Make a Nike T-Shirt?

The cost to make a Nike shirt can vary based on the type of shirt and the production site, but it usually costs less than $10 to the company. Nike manufactures clothing in more than 40 different countries around the world, so the cost to the company will vary depending on things like fair labor laws.

If you want to know how much it costs to order a personalized t-shirt from Nike, the company provides a handy pricing chart on its website. On average, it will cost you about $35 to order a customized Nike shirt.

How Much Does It Cost to Design a Shirt?

It will cost you about $25 to design a custom t-shirt and have it printed. In many cases, the price will easily go up to $35, though this does depend on the printing method you use.

If you want to design and print your own shirt, the cost will depend on what equipment you need to buy. If you already have screen print tools and inks, you can print your own design for just a few dollars. If you need to buy frames, inks, and blank shirts, it will cost you several hundred dollars to get started.

Do T-Shirt Businesses Make Money?

T-shirt businesses can make money, though how much depends on the scale of the operation and the skill of the printer, among other factors. The global custom t-shirt industry has grown enormously over the past decade, and experts anticipate it may grow to 10% more over the coming five years. Everyone loves t-shirts, so it makes sense that the idea of buying a special, unique-to-you tee has growing appeal too!

Here’s the thing, though: you can accurately estimate how much profit you can turn on a single shirt. All you have to do is add up all your costs and subtract that from the price you place on the shirt.

But things like how fast you can print shirts and the quality of your designs will depend on your skill and experience.

You also need to consider the size of your operation. Large-scale printing companies that use DTG printers and have multiple employees running the printers and heat presses will turn a large profit because they sell so many shirts.

If you have a print shop set up in your basement and you can only sell ten shirts a week, you can still make a profit on each garment, but you won’t have a large income from the business.

Conclusion

The average price for a custom t-shirt is $25, but the price from a specific printer can vary a lot, ranging from about $10 to as high as $55. This big discrepancy occurs because different printing methods for custom shirts have varying costs for the printer.

Other key factors that impact the cost of a custom shirt include the number of shirts in your order, as bulk orders sometimes cost a lot less to produce. Shipping costs can also make custom t-shirt prices go up and down.