Delicate cut-outs, crisp geometric shapes, and lacy patterns are popping up on the runway and in a ready-to-wear fashion more and more. But how do designers make these designs without spending hours and hours at the cutting table? Cutting fabric with a laser is the answer.

Laser cutters are a way to cut fabric and other textiles quickly and precisely. The heat from the laser burns or melts through the material to leave a sharp, clean edge whether you’re making a design or cutting out pattern pieces.

The technique isn’t new, but improved technology is making it more accessible than ever. This guide will tell you everything you need to know about laser cutting fabric.

Laser Fabric Cutting: an Overview

Since the invention of the laser in the late 1950s, people have used this technology for thousands of different activities. Lasers are beams of highly focused light that can cut, melt, vaporize, and burn the material you point them at.

Manufacturers started using lasers to cut fabric in the 1970s when they developed the CO2 laser. CO2 lasers can cut non-metal materials like fabric and textiles but aren’t powerful enough to cut through most metals.

The benefit of cutting fabric with a laser instead of traditional tools like rotary blades or scissors is the precision. Lasers can make the same cut the same way over and over again. Whether it’s cutting out hundreds of the same pattern piece or replicating a lace design on multiple fabric types, lasers make the process quick and accurate.

Lasers have different impacts on different fabrics. However, regardless of the fabric type, the laser will only mark the part of the fabric it touches, which eliminates slip cuts and other mistakes that happen with hand cutting.

Initially, these lasers were just for use in factories. Today, there are CO2 laser cutters that you can use at home. High fashion designers and hobbyist makers alike can use this technology for intricate designs.

What Is a Fabric Laser Cutting Machine?

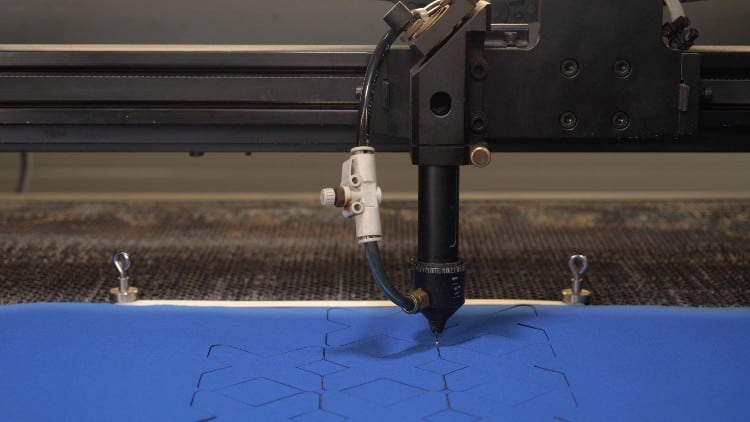

A fabric laser cutting machine is a device that controls a laser to cut or engrave fabric and other textiles. Modern laser cutting machines have a computerized component that can translate computer files into instructions for the laser.

The machine will read a file, like a pdf, and use it to guide a laser over a surface, such as a piece of fabric or an article of clothing. The size of the machine and the diameter of the laser will impact what types of things the machine can cut.

Household laser fabric cutters look a lot like desktop printers or die-cut machines. Bigger industrial laser cutters can handle much larger pieces of material. The commercial cutters are best for large runs of a design or other high-volume work.

What Kind of Laser Do You Need for Textiles?

There are several kinds of lasers, but the one that works best for textiles is the CO2 laser. CO2 lasers push light through a tube of gas, in this case, carbon dioxide, to focus the light into a laser beam. That beam is what cuts the textiles.

The type of light in a CO2 laser is infrared, meaning you can’t see it with the naked eye. Infrared light has intense heat and a long wavelength. This lets it cut through a wide variety of materials quickly and precisely, making it great for fabric cutting.

CO2 lasers have three distinct advantages over other laser types. They are great for textiles because they are adjustable, don’t use too much power, and it’s a non-contact laser.

Changing the amount of light coming through the tube lets you adjust the intensity for different fabrics. This makes the CO2 laser cutter versatile, especially for sewing and fashion applications.

The small amount of power required makes CO2 lasers great for both industrial and home use. They can help manufacturers run efficient and safe factories, and you can use them in your home without overloading your electrical system.

Finally, being a no-contact laser minimizes the damage to the material you’re cutting. The laser beam is precise and only cuts where you direct it to go. There’s nothing to snag or catch on the fabric, so it won’t stretch out as you cut. The result is a crisp cut and smooth design.

What Fabrics Can You Cut With a Laser?

You can cut almost every type of fabric with a laser cutter. No matter what the fiber type is, the laser will give you the same level of control over your cuts and designs. However, the type of material you’re cutting will impact what happens to the edges of the cuts and what other steps you’ll need to take with your project.

Cotton

Cotton is a natural fabric, meaning it comes exclusively from plant material. Laser cutters work on cotton by burning through the material. The cut edges of a cotton garment can turn brown or yellow-ish, like the burnt edge of a piece of paper, if the laser is too intense.

Cotton is a natural fabric, meaning it comes exclusively from plant material. Laser cutters work on cotton by burning through the material. The cut edges of a cotton garment can turn brown or yellow-ish, like the burnt edge of a piece of paper, if the laser is too intense.

You can make intricate cuts on cotton with a laser cutter. However, the laser will not finish the edges. Like any other cut edge on cotton fabric, laser-cut edges can fray. It’s a good idea to go over any exposed or unfinished cut edges with a fray check or fray blocker.

Silk

Silk is a more delicate natural fiber than cotton. It is also an organic material but much thinner than cotton. You can cut silk with a laser easily. Like cotton, it will not finish the edges, so you’ll need to watch for fraying.

Silk is a more delicate natural fiber than cotton. It is also an organic material but much thinner than cotton. You can cut silk with a laser easily. Like cotton, it will not finish the edges, so you’ll need to watch for fraying.

While you can make intricate and complicated designs on silk easily, the thinness of the fabric means that more complex designs will be more prone to tearing than they would be on thicker material. When you cut silk with a laser cutter, use a low setting and avoid tiny shapes.

Felt

Felt is a great fabric for laser cutting because it is a thicker material that holds up well to cutting. There is both synthetic felt and natural felt (made from animal fibers like wool), and either version works well with laser cutters.

Felt is a great fabric for laser cutting because it is a thicker material that holds up well to cutting. There is both synthetic felt and natural felt (made from animal fibers like wool), and either version works well with laser cutters.

The heat from a laser cutter will gently melt the edges of the cuts in a synthetic felt. This melting works to seal the cut, preventing future fraying. Felt cuts will stay crisp for the life of the garment. Natural-fiber felts are a low-fray fabric, to begin with, so they also work well with laser cutting. The cut edges won’t need as much finishing as a cotton or silk cut.

Because it is so thick, felt is often difficult to cut precisely with scissors or rotary blades. Laser cutters solve this problem and open up new possibilities for using felt in your projects.

Leather

Leather is another material that works extremely well with laser cut machines. It’s a low-fray material, so the cut edges won’t need finishing. It’s also a thick, tough material and lasers cut through it much more easily than blades.

Leather is another material that works extremely well with laser cut machines. It’s a low-fray material, so the cut edges won’t need finishing. It’s also a thick, tough material and lasers cut through it much more easily than blades.

The intricate dot designs in leather shoes like brogues are a great example of how you can use a laser cutter for leather. It’s much more efficient to use a laser cutter than to bore the holes individually.

Synthetic leathers are the exception. They are often made with a harmful type of plastic that interacts poorly with the CO2 laser (more on this in the next section!)

Polyester

Polyester is a man-made fabric that works well with laser cutters.

Polyester is a man-made fabric that works well with laser cutters.

It’s sturdy and has a similar thickness to cotton, but unlike cotton, the cut edges will not fray.

The laser beam will melt the cut edges and seal them off.

What Fabrics Should You Never Cut With a Laser?

Lasers are wonderful for a wide variety of fabrics. However, since they use gases to function, there is the possibility of negative chemical reactions with some man-made fibers. It’s important to know the fiber content of your fabric before you use a laser cutter to avoid dangerous situations.

PVC and Foam

Any fabric with PVC, also known as polyvinyl chloride, is dangerous to cut with a laser cutter. Cutting fabrics or materials with PVC in them will create hydrochloric gas. The gas interacts with moisture in the air and the result will corrode the inside of your lungs if you inhale it.

Aside from the serious health risk, hydrochloric gas can also damage the laser in the laser cutter. So what materials have PVC in them?

Any fabric with vinyl contains PVC. This includes most faux leathers. Even PU leathers (polyurethane) can release toxic chemicals in a laser cutter. Craft foam and fabric foam also tend to contain PVC. Do not put these materials into a laser cutter.

Will Laser-Cut Fabric Fray?

Laser cutters do not fray fabrics. However, they do not protect natural fibers from fraying. The laser will melt the edges of synthetic fabrics, especially those that have plastics in them. That melting prevents future fraying and damage to the cut edge.

For natural fibers that don’t melt under the laser, fraying is still possible. The cut itself will not unravel or fray the fabric. It’s a very precise cut. However, the edge will not be protected from the factors that cause fray normally. Movement and tension can still loosen the edges and fibers can unwind from the body of the fabric.

You don’t need to treat cut edges on synthetic fibers that come out of a laser cutter. They won’t need hemming or turning or any kind of fray blocker. Natural fabrics, however, need protection on the cut edges. Depending on what you cut with the laser, that can be a fray blocker liquid or a surged or hemmed edge.

The laser will only cut the parts of the fabric you tell it to cut. Corners, curves, and other shapes that blade cutting leave vulnerable to fraying are less likely to fray with a laser cutter. Even with natural fibers, laser cutting will result in less fraying than blades.

Can You Use Lasers for Other Fabric Applications?

The adjustable nature of CO2 lasers means that you can do more with a laser cutting machine than cut. A lighter setting will let you engrave material instead, opening up the possibility of more intricate designs and applications.

The same machine will both cut and engrave. The intensity of the laser changes what happens to the fabric. The more intense the light and heat, the deeper the laser will go into the fabric. So, mild settings will let you graze the surface of your material rather than cutting through it.

Thicker fabrics are best for engraving. If the material is too thin, the laser could easily cut it instead of engraving. It’s best to test your settings on a scrap piece of your chosen fabric before starting the design. That way, you can make adjustments without ruining your projects or wasting material.

Laser Engraving

Laser engraving is a method of putting a pattern, design, or other decoration onto the material’s surface without cutting all the way through. The heat of the laser changes the material or cuts through the top layer, leaving the piece whole but decorated.

The type of fabric you engrave impacts how the finished product looks. Thicker materials like leather or felt can have a textured engraving that almost looks like carving. The laser will cut down into the top of the fiber without pushing all the way through.

For thinner materials, especially polyesters and synthetics, the laser will lightly melt the fibers, changing the way they look. The texture of these engravings will be more subtle. The most obvious difference will be in color.

Denim, felt, fleece, leather, and polyester are great materials for laser engraving. Depending on the type of dye in the fiber, the engraving can either lighten it (as with many types of engraved denim) or darken it (like an engraved felt or polyester shirt).

Can You Laser Cut Fabric at Home?

This remarkable technology started in factories and commercial settings. The first laser cutting machines were large and needed special skills to operate. The technology has come a long way, but can you laser cut fabric at home?

This remarkable technology started in factories and commercial settings. The first laser cutting machines were large and needed special skills to operate. The technology has come a long way, but can you laser cut fabric at home?

The answer is yes—you can use a laser fabric cutter at home. There are much smaller models available now, so you don’t need an industrial-sized space to bring your laser cutting designs to life. You will need a basic understanding of drawing software such as Adobe or the software that comes with your laser cutter.

But how much does a fabric laser cutter cost? It’s a sophisticated piece of equipment, but you can get a small one for about $200. A high-end machine can run as much as $10,000. Choosing your machine means balancing your budget with the features and size that you want.

Larger machines will cost more, but they can also cut or engrave larger pieces of fabric. You’ll also want to check the depth of the cutting surface. The thinner the surface, the more limited your fabric choices are. For example, cutting one layer of leather will take much less space than putting a long leather jacket in the machine.

If your projects or designs won’t work well with a small, at-home laser cutter, some companies will help you cut your designs with their commercial laser cutters. Depending on the volume of your laser cutting, it may be cheaper to outsource the cutting after you’ve done the designs.

However, if you have the desire to do your own laser cutting at home, it’s possible in just a few easy steps.

How to Laser Cut Fabric at Home

Using a laser cutter on your fabric takes more preparation than cutting pattern pieces or designs with a blade. The trade-off is the speed and precision of the cutting. To get the best cuts every time, make sure you’re testing fabric samples first and keeping your fabric as flat as possible.

Follow these steps to get a clean laser cut, every time.

- Check your fiber content. The first step is the most important. Checking your fiber content will help you avoid PVC and get your settings right. The fiber content will also inform your design. You can make much more intricate patterns on synthetics, so knowing your fiber content from the start will help you make the best cutting choices.

- Prepare your fabric. Once you have your fabric chosen and you know your fiber content, you need to decide where you’re putting the design. For completed garments, it may be helpful to mark where the design belongs while it’s on a body or a dress form so you can envision how the design will hang. When you’re cutting or engraving fabric that isn’t sewn into a project yet, you have more leeway. Either way, make sure you place the fabric as flat as possible on the cutting surface. If the material is wrinkled or dirty, wash and iron it first.

- Test your settings. Before you cut your project, test your settings on a scrap piece of the same material. A test run will keep you from accidentally ruining an entire project. It will also give you an idea of how to secure your project fabric to the machine. Most CO2 laser cutting machines use compressed air to cool the cut edges as you go. The force of this air will blow your fabric around and cause mistakes if you don’t secure the fabric properly. Tape or strong magnets work well. You can test which is better when you run your test fabric through.

- Load your design. When you’re happy with your settings, you can follow the directions for your machine to load the cut design you want. Whether it’s making a lace pattern, cutting out garment pieces, or making personalized engravings, make sure your cut file is compatible with your machine. You may want to run a second test cut with the design to make sure it works the way you anticipate before putting in your project fabric.

- Cut! When your settings and design are ready to go, so are you! Put your project or project fabric onto the cutting surface and secure it, then let the machine take care of the rest.

It’s a good idea to always follow the directions that come with your laser cutting machine. As you get more familiar with what your machine can do, you can reduce the number of tests you do first and spend more time bringing your projects to life.

Conclusion

Laser fabric cutting is an exciting new technique to embellish your sewing projects and elevate your fashion. Whether you invest in your own machine or partner with a commercial cutter, laser cutting is a great way to make complex cuts simple and efficient.

Have you ever used a laser fabric cutter? Let us know your favorite laser cutting tips in the comments below!